New -1mm Sintra PVC Faced Foam Board-For Outdoor and Long term

GENERAL

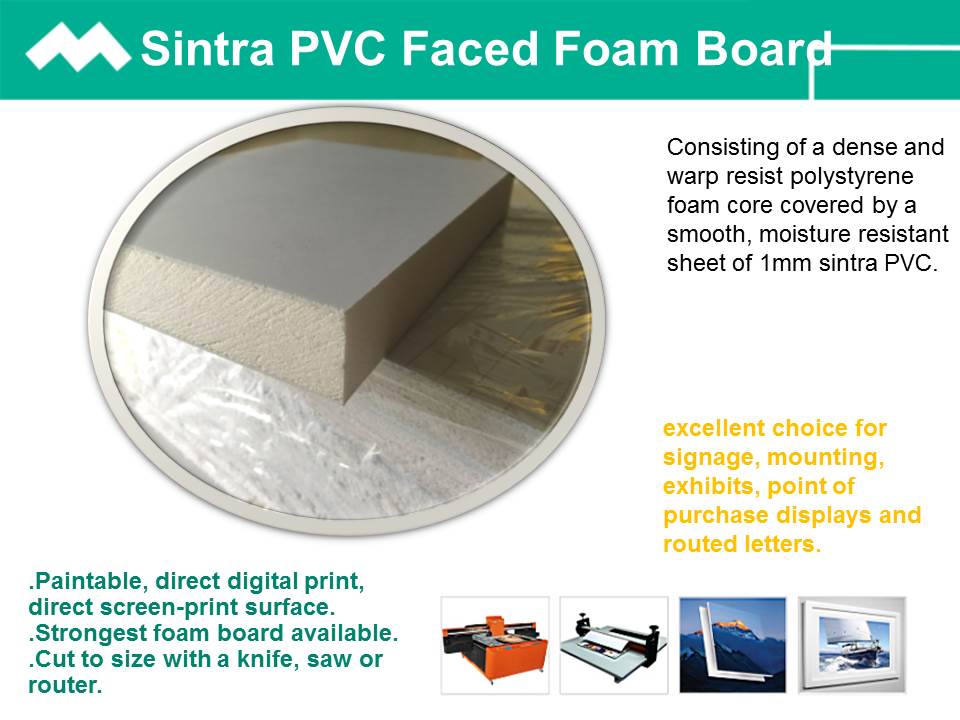

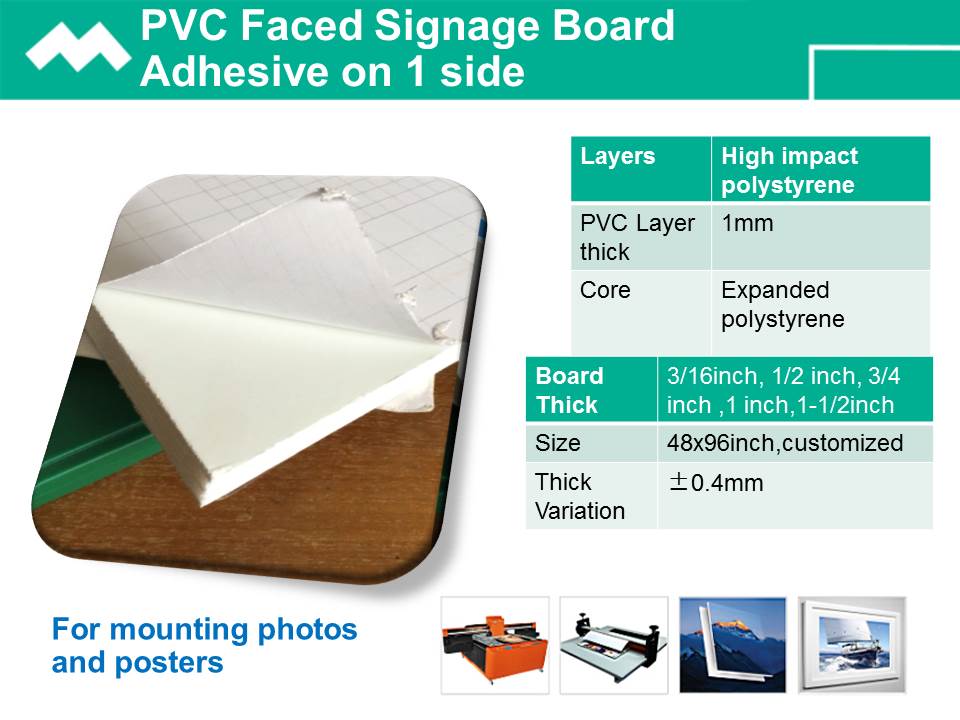

New Product -Yatusi PVC Faced Foam Board is in a lightweight structural panel consisting of a rigid polystyrene foam core faced on both sides by a smooth, moisture resistant sheet of 1mm expanded PVC.

FACING SURFACES

Yatusi PVC Faced Foam Board have 1mm white expanded PVC facers. Colored facers are available on a custom order basis.

CUTTING

CIRCULAR SAWS: Yatusi PVC Faced Foam Board may be cut with standard table saws. For best results, use a blade designed for cutting Yatusi PVC Faced Foam Board. The specifications are:

LAMINATING / GLUING:

No special surface preparation is required when gluing to the face of Yatusi PVC Faced Foam Board. The surface should be kept clean and free of any oil contaminates as with any other surface to be glued. The selection of the proper adhesive depends on the materials to be joined. As a general guideline pipe cement, contact adhesive, construction adhesives and pressure sensitive tapes are compatible with the Yatusi PVC Faced Foam Board facers. Caution should be taken when using solvent-based adhesives not to allow adhesive to make contact with the polystyrene core. These types of adhesives are likely to attack and deteriorate the foam core. Any adhesive should be thoroughly tested to evaluate its suitability.

PAINTING

GENERAL: Yatusi PVC Faced Foam Board needs no special preparation before priming or painting. For best results the surface should be clean and free of any oil contaminates. Cleaning the panel with glass cleaner or isopropyl alcohol just prior to coating can accomplish this.

TYPE OF PAINT: The following paints have shown excellent results when used on Yatusi PVC Faced Foam Board.

Caution should be taken when using oil base or solvent base systems, not to allow paint to make contact with the polystyrene core. These types of paints are likely to attack and deteriorate the foam core.

In cases where the foam edges might be subjected to exterior exposure, it will be necessary to protect the edges from deterioration by the high intensity ultra violet light of the sun. A good coating of water-base paint or similar U.V. barrier should be sufficient to provide this protection.

Caution should be taken with any paint, especially when intended for outdoor use. Always test paint on Yatusi PVC Faced Foam Board prior to production run and follow all of the paint manufactures instructions.

SCREEN PRINTING:

GENERAL: Yatusi PVC Faced Foam Board are rigid, lightweight and easy to handle. The surface of Yatusi PVC Faced Foam Board has a closed cell matte finish that makes screen printing easy to accomplish.

Caution should be taken with any ink. Always test ink on Yatusi PVC Faced Foam Board prior to production run. Allow 24 - 96 hours after test printing to evaluate the suitability of the ink for the intended application. Follow all of the ink manufacturers instructions especially regarding any required ink additives such as catalyst for proper adhesion and exterior usage.

SURFACE PREPARATION: For best results in screen printing Yatusi PVC Faced Foam Board panels, it is recommended the panels be cleaned to avoid the clogging of screens. This can be accomplished by wiping the panel with a tacky cloth or by cleaning the panel with isopropyl alcohol or glass cleaner prior to screening.

DRYING: Drying by oxidation and evaporation is recommended. Allow the freshly printed Yatusi PVC Faced Foam Board to dry the length of time suggested by the particular ink manufacturer.

ULTRA VIOLET INKS: Most U.V. inks that are compatible with expanded PVC can be used with Yatusi PVC Faced Foam Board. However, board thickness, type of ink, wattage of U.V. lamp and exposure time can affect results. Always test the suitability of the ink and the drying process for your particular Yatusi PVC Faced Foam Board thickness. Allow 24 - 96 hours after test printing to evaluate the results. Follow all of the ink manufacturers instructions.

PHOTO MOUNTING

GENERAL: The surface of Yatusi PVC Faced Foam Board makes it an excellent material for pressure sensitive photo mounting. Because of the rigidity of panel, finished mounts are stronger than mounts using lighter foam-type substrates.

SURFACE PREPARATION: The surface should be clean and free of any dust, oil or other contaminates prior to mounting. This can be accomplished by wiping the panel with glass cleaner, a tacky cloth or with isopropyl alcohol.

PRESSURE SENSITIVE MOUNTING: Cold mounting in cold roller laminators or hand lamination give excellent results. The choice of film is the most important consideration when using pressure sensitive film for mounting. Before using any pressure sensitive material, contact the manufacturer for recommendations concerning the use of their respective laminating materials in conjunction with Yatusi PVC Faced Foam Board.

DRY MOUNTING: Dry mounting is not recommended with Yatusi PVC Faced Foam Board. The panels may tend to warp when heat is applied to only one side of the panel.